Fourth-generation executive Gillian Taylor, director of G.H. Hurt & Son, on embracing tradition while remaining relevant with today’s consumers.

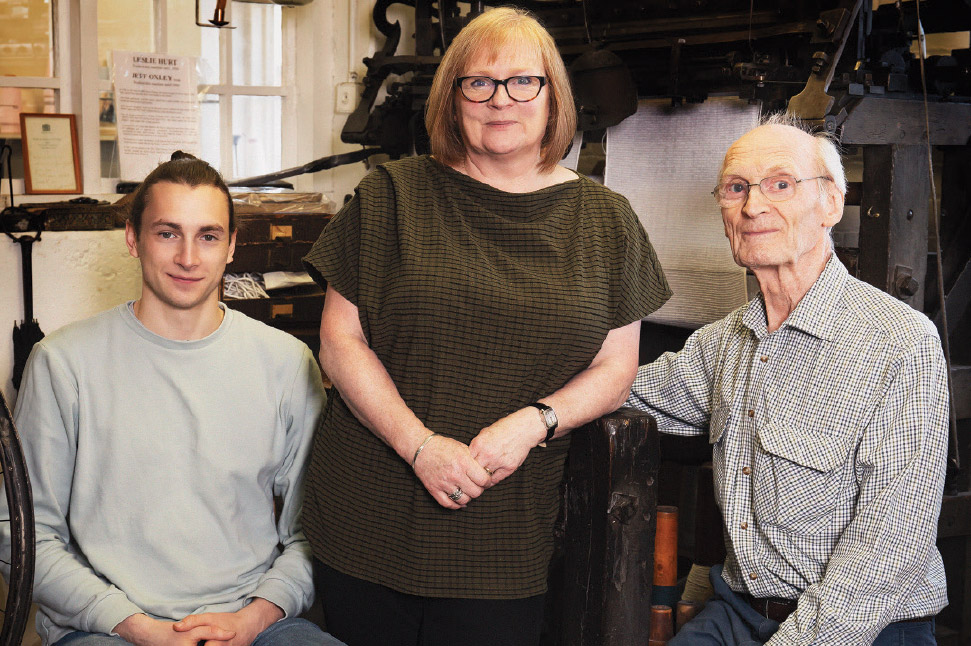

Director Gillian Taylor (center) is supported by her father Henry Hurt

(right) and son James Taylor (left).

Like Willy Wonka opening the gates of his mystical chocolate factory, Gillian Taylor spent weeks last month preparing for G.H. Hurt & Son’s annual public showcase during England’s Heritage Open Days festival. As one of the 5,000 participating historic events, hundreds of curious patrons traveled from near and far to tour the family company’s headquarters that includes the largest collection of authentic hand frame knitting machines—designed by Rev. William Lee in 1589! To add historical perspective, veteran staff stationed around the Nottingham factory provided briefings and answered questions. It was a memorable day, one that never gets old, for G.H. Hurt & Son to showcase its rich history while simultaneously proving it’s still going strong.

“With over 100 years of heritage, we certainly have a lot of stories to share,” Taylor says of the traditional lace-knitting company launched in 1912 by her great grandfather, George Henry Hurt. “Our modern knitting machinery stands alongside some of the original hand frame knitting machines—one of the most extensive collections in the world and a reminder of how far we’ve come.”

Small Talk

What was your first paying job?

We had a renowned rose grower not far from where I grew up in Nottingham, England. I got a summer job working in the garden. Perhaps that inspired my love for color and design?

What’s inspiring you?

I designed a scarf recently where the inspiration came from a car park, of all things. It had these wonderful hexagonal shapes on the front of it.

If you could hire anyone, who would it be?

Sir Paul Smith, the iconic British designer. He’s local and so passionate about his designs.

What’s the last movie you saw?

The Favourite, starring Olivia Colman as Queen Anne. Well worth a watch!

Who’s your most coveted dinner guest?

David Attenborough. He brings the natural world into our homes, inspiring millions of people to preserve the world and

address environmental issues.

What are three items you can’t live without?

Nespresso coffee machine, a device to play music, and fruit.

Often referred to as “The Shawl Factory,” G.H. Hurt & Son has built a long-trusted reputation designing and manufacturing high-quality women’s shawls and scarves, baby christening shawls and a variety of other lace-knitted goods. Still producing out of its original location—an old seed warehouse, built in 1781—Taylor is currently focused on modernizing operations and connecting with younger customers, relaying G.H. Hurt & Son’s rich history through an updated website, social media strategy and live events like Heritage Open Days. “You have to be in the action—that’s how branding works today,” the exec says. “Now, more than ever, it’s important to be clear about who you are and ensure you tell your story in an honest, genuine way.”

Originally an old seed warehouse, built in 1781, G.H. Hurt & Son has operated in the same historic building since launching in 1912.

Taylor has been doing just that since following in her father Henry Hurt’s footsteps and joining the business in 1983, at age 18. Her career salad days was a period of relative stability and success, when G.H. Hurt & Son employed up to 40 staff members. However, the ’90s proved to be a challenging time—for all British manufacturing. The local knitting industry faced increasing low-cost competition from suppliers in Asia. It became a case of adapt or die. The company teamed with designers around the world while it updated its delicate lace-knitting processes to create relevant and interesting goods. Taylor’s knack for spotting the latest trends added a new dimension and enabled G.H. Hurt & Son to partner with many international design houses, such as Burberry, Dior and Paul Smith. She followed that successful endeavor in the early aughts by championing a rebranding and introducing the company’s first private label, the Heritage Collection, featuring a blend of traditional yet modernized patterns and hues. Taylor also fine-tuned the company’s online presence to attract a broader global audience. “As retail has consolidated, we haven’t been able to replace many of our white label clients,” Taylor says. “Instead, we’ve naturally began putting more focus into the creation and branding of our own label.”

Taylor, however, is equally committed to the success of its retail partners, which spans hundreds of boutiques worldwide. “They will always come first,” she says, adding, “Quite frankly, our product is meant to be sold through a retailer. We need someone who knows our story and can educate the customer on the piece of history they’re holding in their hands.” It’s one reason why G.H. Hurt & Son isn’t sold just anywhere. Retail partnerships are selective and cultivated over time. “We’re very cognizant of who we sell to and what we sell,” Taylor says. “We’re not going to sell a boutique the same product as its neighbor around the corner. That doesn’t benefit them or us! We want everyone to have success.”

Two more key ingredients to the company’s success at retail: uniqueness and quality. “It’s important to remember that a good qualityproduct extends far beyond the product itself,” she says, noting that it’s about going the extra mile with great customer service, sustainable packaging and all the other bits that make the customer experience memorable. “That’s what has kept G.H. Hurt & Son relevant over 100 years later.”

Another factor in keeping G.H. Hurt & Son relevant all these years is its long royal customer blood lines. It all started with Queen Elizabeth II purchasing a shawl when Prince Charles was born in 1948. The prince continued the tradition with his wife Princess Diana, using G.H. Hurt & Son’s baby shawls for their newborns, Prince William and Prince Harry. In turn, the Duke of Cambridge, William, and his Duchess, Catherine, have relied on the trusted manufacturer over the last decade, selecting a new design for each of their three children: George, Charlotte and Louis. And most recently, Prince Harry and wife Meghan Markle introduced their first son, Archie, to the world in May, wrapped in an ornate G.H. Hurt & Son design that takes up to three days to create. The exposure has been (quite) good for business—a sales bump with each royal baby’s public debut. “From the moment the couple steps out of the hospital, it doesn’t take the public long to go find our website,” Taylor confirms. “It’s so exciting that we’ve been able to continue our tradition of lace-knitting with future generations of the royal family.”

The far-reaching publicity does come with its fair share of challenges—like keeping up with production demands and making sure shipping runs smoothly. It’s Taylor’s job to make sure it all goes right. “With information moving so quickly, businesses must be ready and responsive,” she says. “We have to put in many extra hours and invest heavily in systems to keep up with orders. But it’s all worth it as G.H. Hurt & Son would have never been able to reach a global market this effectively without the incorporation of wonderful new technologies.”

On that note, Taylor says G.H. Hurt & Son’s formula for success going forward is a marriage of technology and tradition that produces exceptional quality garments. Ever since gaining traction with its knitted striped mohair scarves and lace fabric for flapper dresses in the ’20s, quality has been the company’s driving principle. It’s why items are often passed down from generation to generation as cherished family heirlooms. In fact, silk-lined lace jumpers and bedjackets crafted from its finest lace fabrics have become sought-after vintage items, including mohair shawls like the one featured in the 1939 classic, Gone With the Wind. “Quality is everything at G.H. Hurt & Son,” Taylor says. “It’s a challenge to achieve and a process perfected over time, but we make it happen.”

What’s the secret to a century-plus of company longevity?

It’s our willingness to always move forward as a business and a family, really. That’s what keeps us relevant. Even when the modernizing of technology first threatened traditional hand frame knitters back in our earliest years, my great grandfather persevered with his entrepreneurial dream and found ways to adapt and survive. I believe the leadership with each new generation has been particularly good at evolving the business to meet the needs of the modern consumer—even during the toughest times. We’re very much a family firm. My son has just finished university and will be coming to join us as fifth generation. But it’s not just the Hurt bloodline that has stayed loyal to our company. Several families have long times to our company as hand frame knitting is often a skill passed through generations.

Who are some of those families?

Frank Oxley was one of the original hand frame knitters that joined our firm back in 1912. His frame was used prior to 1912 in Oxley’s Frame Shop in Park Road, Chilwell—just a few steps away from our present factory. Frank knitted his hand frame at the firm until 1948 and became a father to four sons and two daughters. Two of his sons, Ernest and Harold, joined the company. Ernest worked on his hand frame until 1952 and Harold until 1972. Harold was known for his efficient production and could produce around 60 scarves in an eight-hour day! Both of their wives were also employed by G.H. Hurt & Son for finishing trades, such as pinning out. Ernest and Harold’s cousin Jeff, was our last hand frame knitter, who worked for us until 1984. Then there’s Reginald Robbins, who is our current head knitting mechanic. He started as an apprentice at age 16 in 1971 and now manages all factory machinery, from our authentic hand frames to our modern computer-operated machines. When Reg first joined the firm, his mother, Marg, and grandmother, Vi, were employed here in finishing trades. Reg even met his wife here, Jayne Wilson, the daughter of Irene Wilson, who joined the firm in 1986.

What do you think it is that makes working at G.H. Hurt & Son a life-long family affair?

There’s something exhilarating about being a part of such a long-standing company and producing this artisanal product that’s respected by everyone, from regular moms to royalty. We’re such a good-hearted group, it just makes sense to want your children to have the same rewarding work experience. It’s a unique opportunity to hold a spot in G.H. Hurt & Son’s history, so why not pass it on?

You mentioned earlier having survived the ‘toughest times.’ What are some examples?

My grandfather fought in World War I and then returned home, at age 20, in 1918, and first worked alongside his father and later managed to sustain the firm through World War II. At the helm, he weathered many restrictions on raw materials and skilled labor. This was perhaps the toughest period in our company’s history. But ultimately, Harrods began buying G.H. Hurt & Son’s shawls in the ’40s, and the company’s reputation for its exquisite fine lacy knitting surged. During the ’60s and ’70s, my father worked hard to convert traditional lacy patterns from hand frames to specially adapted powered knitting machines. It revolutionized the business and enabled an increase in production.

Did you always intend to join the family business?

To be honest, not quite. I’ve always had a love for animals and thought that one day I might become a veterinarian. Funny enough, my daughter is taking on that profession now! But once I realized I was more creative than scientific, I decided to continue my path with the family business. No one pushed me. It just turned out to be a natural fit.

Any regrets?

None! It’s been such an exciting chapter in my life—so much new technology and subsequent growth to be had. I’m proud to have built the digital side of our business significantly. That includes hiring a photographer and an entire digital marketing team. We’re also selling our brand online direct-to-consumer (DTC) for the first time, which has been extremely beneficial.

Taking into account the rise of DTC as well as online competition in general, what might a traditional childrenswear store look like in five years?

Wow, that’s a difficult question. Things are changing fast, aren’t they? The stores that will remain are the ones that focus on purchasing quality products and offering great service. Customers have always told us how much they appreciate our old-fashioned customer service. We hope our shawls go into stores that offer a similar level of service. While it may seem like everything is centered on quick delivery, I promise you, the human connection is still very much prevalent in capturing repeat sales.

What specifically does “old-fashioned customer service” entail?

Success and convenience are more closely linked than ever. With that in mind, I’ve focused on providing our retail partners the assets they need to build our brand with the most ease. That means high-quality photography, detailed background story on the brand, uncompromised product quality, on-time deliveries and clear communication over the phone and email. As you know, the retailers that are surviving are the ones that offer a service. So, as a brand, we want to give them a unique product with a unique story to tell without any added hassle. That’s how we’ll both stay ahead, even in tough times. Take our knit scarves and shawls of fine kid mohair, for example. We’ve been making those exact same designs since 1912! Recently, I lost a supplier for that yarn, and it took me more than three years to find somebody who could spin it in the way we require for our shawls. It’s all part of our heritage, and that’s something we’ll never compromise.

How’s business been this year?

We’ve had a really good year. We’re gradually trying to build our business internationally with the States being our second

biggest market to the U.K. We’re off to China next week to explore opportunities for growth there, as well. We’ve received a lot of interest, but we want to take things slow and make sure we’re doing all the right things at the right times.

Any projections for the rest of the year?

We just launched a beautiful cashmere shawl that can be personalized through our website, so we’ll be continuing to closely track the success of that product. Even at a higher price point, customized items are proven to be very popular. I expect we will be adding more personalization to our range in seasons to come.

Any plans yet for your 110th anniversary celebration?

Nothing specific yet. However, for our centenary we had a wonderful day. We were honored that Sir Paul Smith came. And the local historical society hung a blue plaque on our factory in recognition of our 100-year anniversary. There are quite a number of such plaques hanging on buildings around London, and we’ve been lucky enough to receive one too. In fact, Smith, who hails from just down the road, helped us unveil it. He used to cycle past our factory when he was young to visit his auntie down the road. I’m sure we will make more wonderful memories for our 110th anniversary. We’ve just been too busy to think about it! •

Leave a Comment: